“Ship Head” auger bits are wood-boring auger bits with protruded cutting lips. These bits generally have a hollow centre, and one flute construction without any outlining spurs. A common misconception is that the thickness of the flute determines the hole size, which is not the case.

Before we understand the reasons why the flute size does not indicate the size of the hole, we first must understand how a wood auger works.

These bits are designed to drill holes in wood and similar materials rapidly and efficiently, requiring the least amount of effort. The actual drilling is done by the cutting lips, whereas the fluted portion of the bit is designed to remove the wood chips. The drill body is smaller than the holes produced by the bits, which causes the least amount of friction between the wood and the tool. Heat kills tooling so the less friction the better.

So, considering how wood augers work, let's delve into how to measure the bit size.

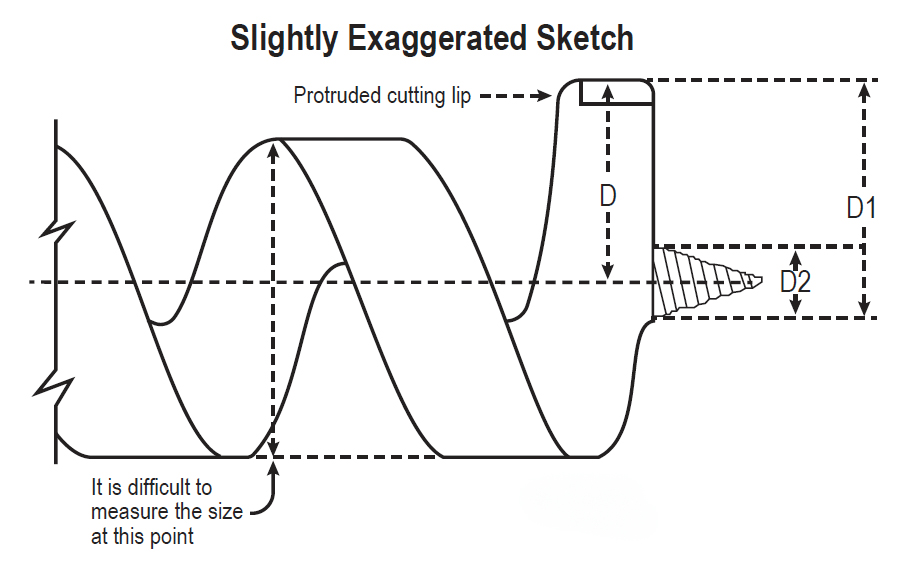

Users often attempt to measure the actual size and thickness of the flute portion to determine the hole size that it will drill. However, it’s very hard, if not impossible to take these measurements because of the odd shapes of the bits.

It is important to understand that the measurement obtained in this way does not have any reflection on the actual hole size drilled.

The measurement that determines the hole size is the distance between the centre of the screw point and the outer edge of the cutting lips. However, it is also difficult to take this measurement because of the odd-shaped parts.

See below the correct measurement process:

A) Measure the distance between the opposite side of the screw point at its base and the outer edge of the cutting lips (D1).

B) Measure the thickness of the screw point at the base (D2)

C) Subtract 1/2 of the (D2) measurement from (D1) to obtain the radius (D) of the bit.

D) Multiply the above figure (radius) by a factor of 2 to obtain the diameter of the nominal bit size.

What about nominal bit size?

What about nominal bit size?

It can be assumed that auger bits should produce holes equal to the nominal bit size. However, the holes made by this type of wood auger vary considerably depending upon various factors such as the type of wood, and dryness of the material. Generally, the softer the materials, the smaller the holes produced.

Green timber that is still wet inside will produce a smaller hole, as the timber will expand after the hole is drilled.

But why?

Well, the screw point often moves around during the drilling process, especially when in softer woods, and the holes produced come out smaller.

So, to wrap this up, the holes produced by these ship head auger bits, in all likelihood, come out smaller than the normal bit sizes. Since workpiece materials cannot be predicted, nominal bit sizes are selected by the theoretical hole size by most manufacturers.

However, when the hole size is critical it’s always recommended that the user selects bits slightly larger in nominal size. For example, when using 18mm bolts or dowels, 19 or 20mm nominal bit size should be used.

Alpha wood auger range

Alpha provides a versatile selection of traditional shipper augers and heavy-duty augers, suited for all your wood drilling tasks. Our shipper augers are perfect for softwood, while the heavy-duty augers are built for tackling hardwood. Though similar in shape to the shipper auger, the heavy-duty model is designed for more demanding jobs, featuring a reinforced design with a hardened screw tip for durability, a rust-resistant coating, and a 7/16 quick-change shank.